Sashimi Knife 240mm

Includes:

- Kurouchi 'Sashimi' Kitchen Knife (handcrafted from Aogami No. 2 steel, 24cm blade length, 170g weight)

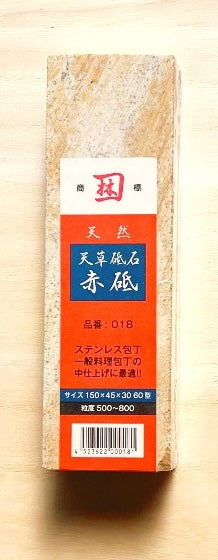

- Red Sharpening Stone (15cm x 4cm x 3cm)

- FREE WORLDWIDE SHIPPING

This is a handcrafted double-bevel knife made from Aogami No. 2 steel and soft iron. It was crafted using traditional "Hon-Warikomi" techniques at the Nakamura Hamono smithy in Oita Prefecture.

Sashimi knives are great for cutting thin slices of foods such as fish and meat.

It has a chestnut wood handle, and the blade is engraved with the signature of the smithy. The pack includes a small whetstone you can use to keep your blade clean and sharp.

*Each knife is crafted by hand, so there may be slight variations in weight and dimensions. We ask for your kind understanding.

*Depending on the number of orders and smithy availability, it can occasionally take up to 3 weeks for your knife to ship.

*This knife is made from steel, so it is normal for a certain amount of rust to form over time. Please use the sharpening stone included with your order to remove any rust. You will find a video which explains how to sharpen your knife at the bottom of this page.

*Depending on the value of your order and local import rules in your country, you may be required to pay additional import taxes when your package arrives.

Nakamura Hamono, The Craftsmen Behind Oita’s Hand-Forged Blades

AS FEATURED ON YOUTUBE

Watch Nakamura Hamono forge knives and tools by hand, 120 years of tradition, still alive in Nakatsu.

OVERVIEW

Nakamura Hamono was founded in 1900 by master smith Eiji Nakamura, who trained under local sword makers in Nakatsu City, Oita Prefecture. Originally established as a kama (sickle) forge, the workshop expanded its craft under the second generation to include specialised tools such as warakiri, or rice straw cutters. Now led by the fourth generation, the Nakamura family continues to run the forge as a family operation, with father and son working side by side and the mother managing customer relations.

Over 120 years later, the smithy remains one of only two blacksmith workshops still active in Nakatsu. The name Nojiyama-naka, or Marunaka, reflects an old regional custom where forges combined local place names with surnames to distinguish their shop.

This heritage continues today in a workshop known not only for kitchen knives, but also for hand-forged sickles, shears, hoes, and field tools used by chefs, farmers, and tradespeople across Japan. Every piece is crafted in-house using traditional methods, with a focus on precision, durability, and connection to community.

PHILOSOPHY AND PROCESS

Crafted in Nakatsu, Trusted Worldwide

Nakamura Hamono has been forging blades in Nakatsu City, Oita Prefecture since 1900, when Eiji Nakamura established the workshop after training under local swordsmiths.

Now in its fourth generation, the family-run forge is led by Tetsuyoshi Nakamura and his son Kozo, with the mother managing customer care. Their small-scale production continues in the same workshop where it all began. Today, Nakamura knives are trusted by chefs, craftsmen, and collectors not only in Japan but around the world. Despite growing international recognition, every blade is still crafted in-house using traditional tools and methods.

A Family Forge with a Purpose

At Nakamura Hamono, craftsmanship is personal. Every knife is shaped, sharpened, and finished by hand, with production intentionally kept small to preserve quality. The family does not operate like a factory.

Kozo Nakamura continues to train under his father, learning the same techniques passed down since the Meiji era.

Alongside their core products, the family provides lifetime maintenance for each blade, including sharpening, repair, and reconditioning. This approach reflects their philosophy: trust comes first, and every tool should be built to last and serve its user well.

Forged, Ground, Sharpened, and Fitted by Hand

Nakamura blades are made using traditional high-carbon steels such as Blue #1 and Aogami, selected for their edge stability and fine grain. The entire process, from forging and heat-treating to grinding, sharpening, and handle fitting, is carried out within the Nakamura workshop.

This hands-on process ensures quality at every stage and gives each knife a unique character. With subtle forge markings, hand-polished handles, and an edge finished in three stages, every Nakamura knife carries the mark of its maker and the legacy of a craft honed over generations.

MESSAGE FROM THE MAKERS

We are the Nakamura family, fourth‑generation blacksmiths from Nakatsu. Every blade we forge carries not only steel, but our years of dedication and care. We do not chase speed or scale. Instead, we focus on tools made to work and last.

Our promise is simple: you will have our support for life. We sharpen, repair, and recondition every blade we create. When you choose a Nakamura knife, you choose trust, continuity, and the quiet confidence that comes from true craftsmanship.

How to Sharpen your knife

Caring for your knife will make it last you for decades. After use, wash it with clean hot water, dry it off thoroughly, and place it in newspaper to prevent rusting. Check out the video below for more information on how to sharpen your knife with a sharpening stone, and how to store it safely.