To our customers in the US: From Aug 29, 2025, new U.S. customs rules may cause longer delivery times, and all orders from Japan will require higher import fees (often US $80–$200 or up to 50%) to be paid by the customer upon delivery.

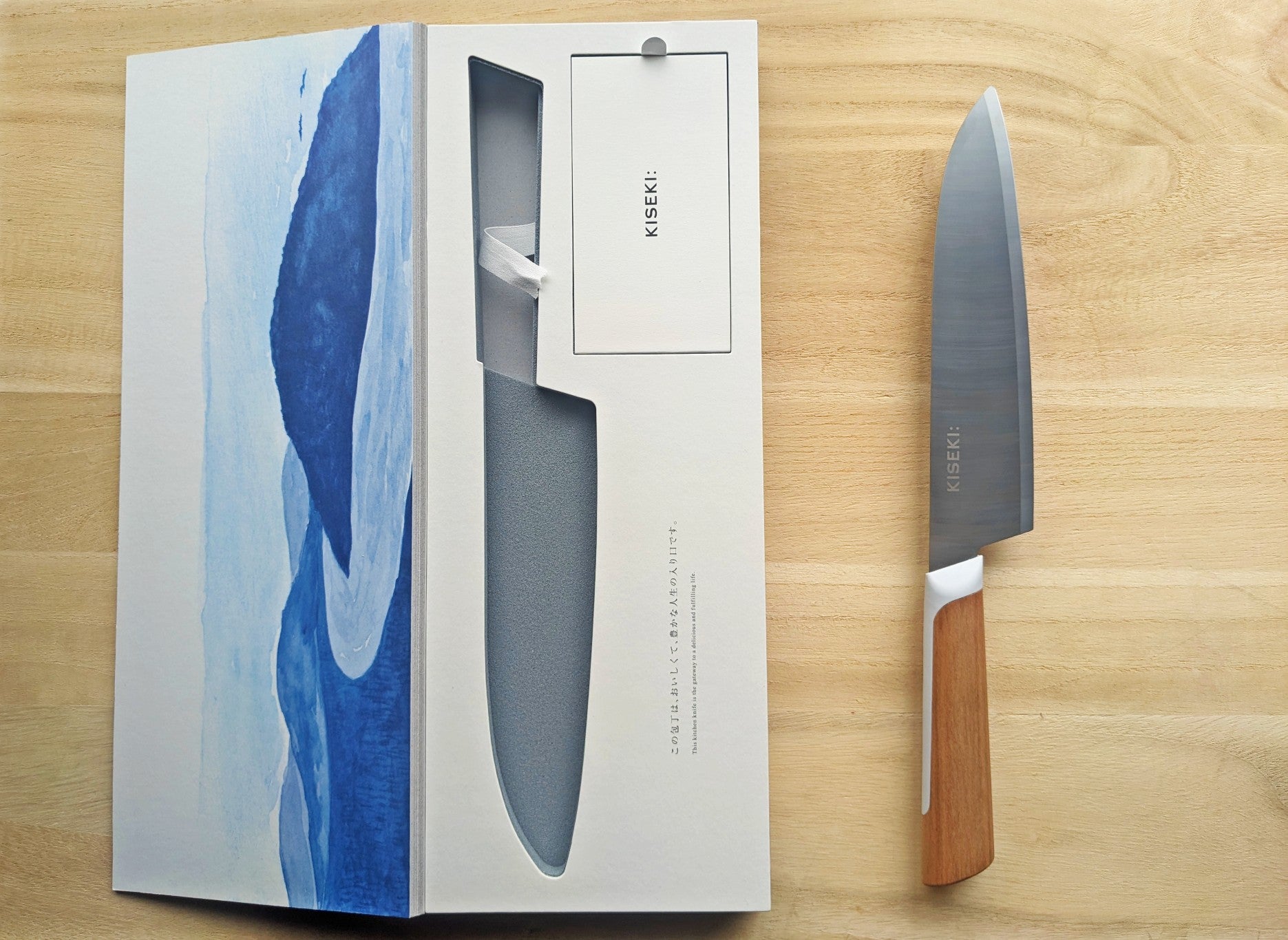

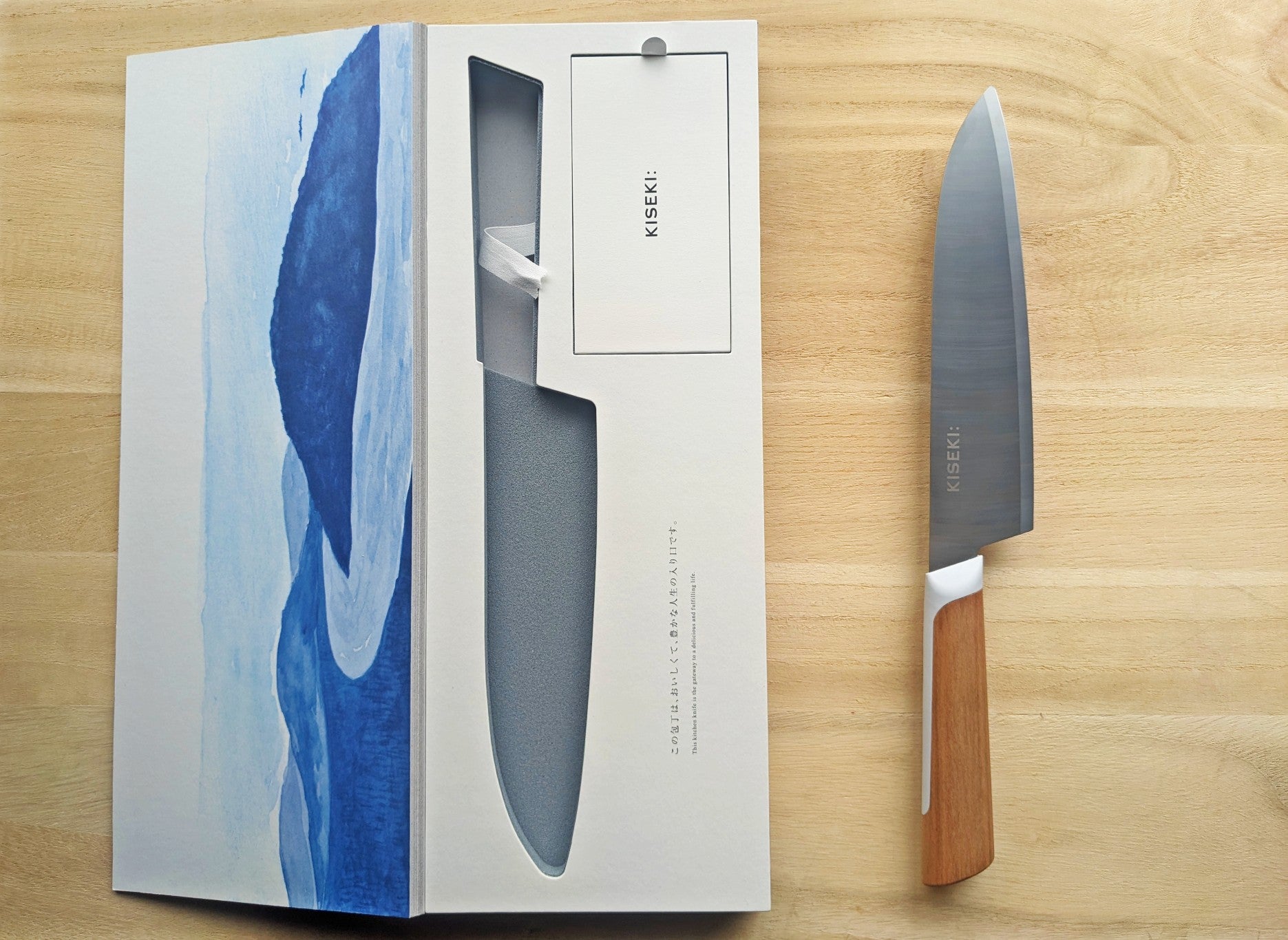

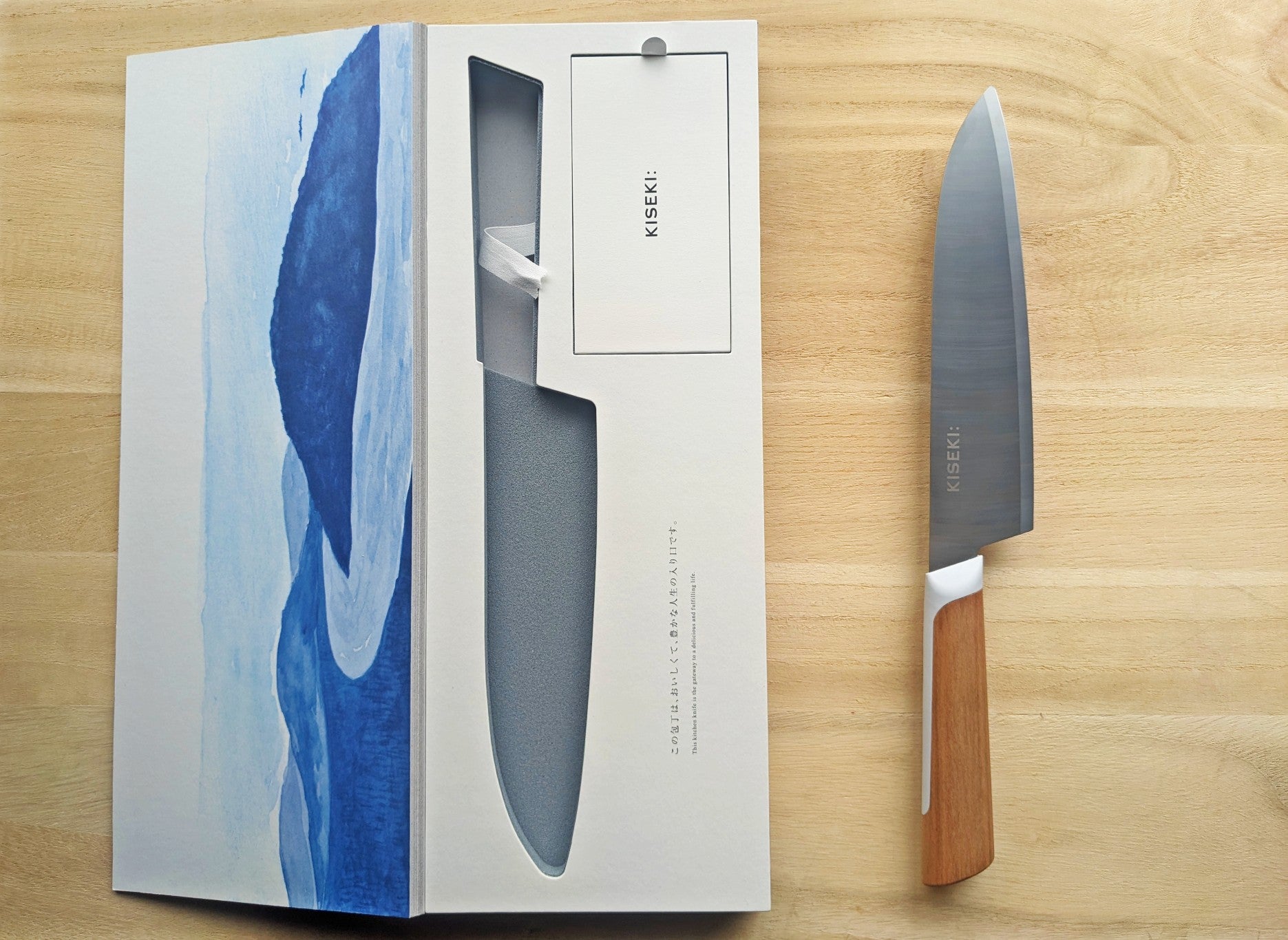

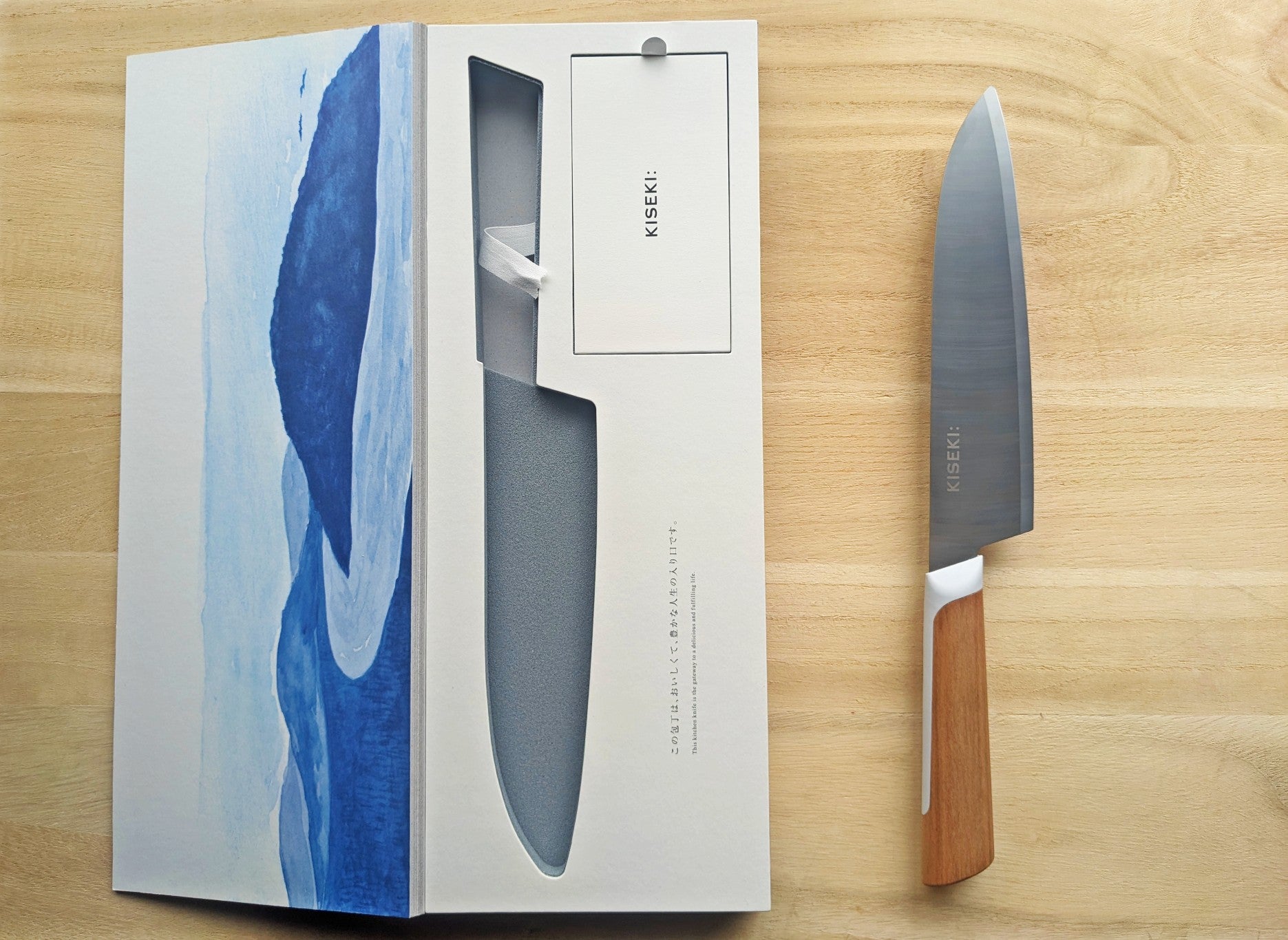

KISEKI Santoku Knife

Ships in approx. 4 months

Discover the delicious sharpness of the KISEKI knife series. The KISEKI Santoku knife features a razor-thin 1.2mm tungsten carbide blade (KS111), crafted to perfection after years of development and over 100 prototypes. Scientifically proven to enhance taste by preserving the fibers and moisture of ingredients, it brings out the natural sweetness in vegetables and the full flavor of meats and fish.

The handle is made from natural wood sourced in Gifu Prefecture, available in three options—Mizunara Oak, Yamazakura Cherry, and Beech—each with unique grain patterns that make every knife one of a kind. Finished with a protective polyurethane coating, they feel comfortably smooth from day one.

Crafted in the legendary blade city of Seki in Gifu Prefecture, this double-edged Santoku is not only rust-resistant but remarkably lightweight at just 140g, making it ideal for daily use.

OPTIONAL: Add the KISEKI diamond whetstone, which is specifically made to keep the sharpness of your KISEKI cemented carbide blade.

The whetstone has one-sided (#1200) grit and comes with a knife attachment made of PP+ Ceramic, that helps creating the perfect angle for sharpening, and a natural wood base.

Specifications

-

Blade Length: 180mm (Total Length: 320mm)

-

Width: 42mm

-

Weight: 140g

-

Blade Material: KS111 Tungsten Carbide (cemented carbide alloy)

-

Handle: Natural Wood (Oak, Cherry, Beech)

-

Muzzle: Glass fiber reinforced polyamide resin

-

Blade-Type: Double-edged

-

Made in: Seki-shi, Gifu, Japan

*Depending on the value of your order and local import rules in your country, you may be required to pay additional import taxes when your package arrives.

KISEKI: The Blade That Preserves Nature’s Flavors

AS FEATURED ON YOUTUBE

Watch the making of KISEKI: Discover how a 126-year legacy and cutting-edge engineering come together to craft a knife so sharp it preserves every flavor.

OVERVIEW

In the heart of Seki, Japan’s legendary city of blades, a new chapter in knife-making has emerged. KISEKI is the first kitchen knife in Japan forged from cemented carbide, a material once reserved for industrial tools.

Developed by Fukuda Hamono, a 126-year-old specialist in precision cutting instruments, KISEKI blends science, engineering, and tradition to create a knife that cuts not only with unmatched sharpness but with a taste of miracle, bringing out the pure flavour of every ingredient.

PHILOSOPHY AND PROCESS

A New Standard in Sharpness

For centuries, Japanese blades have balanced artistry and performance. Yet, traditional steel knives came with trade-offs, carbon steel rusts, stainless steel dulls.

Seeking a better way, engineer Keisuke Fukuda set out to combine the best of both worlds, pioneering the use of ultra-hard cemented carbide in a kitchen knife.

The result is an edge that glides effortlessly, holding its sharpness longer than conventional blades.

Heritage Refined through Engineering

Creating KISEKI required pushing beyond the limits of conventional knife-making.

The dense, weighty carbide cannot be pressed or laser-cut like steel. Each blade is wire-cut over ten hours with 1/1000 mm precision, then finely ground using diamond wheels to achieve a razor-thin edge that preserves the cellular structure of food.

Every knife is made to deliver the same flawless quality, every single time.

Crafted for Flavor, Designed for Life

More than just a tool, KISEKI is a gateway to better cooking. Independent tests show that its precise cut locks in juices, reduces oxidation, and enhances natural flavors.

Handles crafted from local Gifu hardwoods connect the knife to its birthplace, blending advanced engineering with the warmth of traditional materials.

The result is a kitchen knife that transforms ingredients into cuisine, creating meals that bring people together.

MESSAGE FROM THE MAKERS

“We believed a knife could do more than cut it could make food taste better.Our mission was to achieve the impossible: a blade that never compromises on sharpness, durability, or flavor. KISEKI carries the legacy of Seki’s craftsmanship into the future, combining century-old expertise with cutting-edge engineering. We hope every slice you make brings joy, connection, and a deeper appreciation for the gifts of nature.”

—The Engineers of Fukuda Hamono

How to Sharpen your knife

Caring for your knife will make it last you for decades. After use, wash it with clean hot water, dry it off thoroughly, and place it in newspaper to prevent rusting. Check out the video below for more information on how to sharpen your knife with a sharpening stone, and how to store it safely.